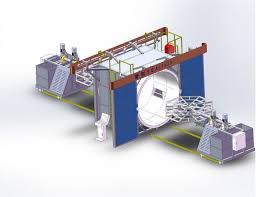

Rotational Molding the Rotomolding could be the process of plastics. The specialty of this practice is it aims for nearly a limitless life span. It is also called rotational casting. There really are a wide range of materials out there for the same. However, the absolute most Custom Rotational Molding commonly molded material could be the grade of PE (polyethylene). These services and products might be created of almost any form and dimensions with excellent capabilities from Tornado Shelters, garbage cans, toys to Air Cargo Containers. The applications of these merchandise are never-ending.

The Demands of rotational Molding

Rotomolding takes a mould for providing almost any product or component. To find the mould, one may take to several procedures like casting, casting, and machining.

The molds for Rotational Molding are made up of Aluminum, and also resources have been recovered from Carbon Steel or Stainless Steel.

It’s suggested that you should utilize experienced people as soon as it has to do with rotomolding layouts and methods to better save your cost.

It is imperative to tackle most of the functions and features of this desirable component or product during the phase of planning it.

Benefits of rotomolding

The molds are required rotomoldingare built from Aluminum. The benefit of exactly the exact same is that unlike any Carbon steel, Aluminum performs far better at the cooling system cycles of Molding. The reason being the simple fact that exposing it makes it wear easier compared to carbon steel as steel begins massaging and transports the rust to molded services and products too.

Some tools are likewise manufactured out of metal.

Aluminum is a lot easier to keep up and modify as compared to carbon steels.

The products are more durable and have a lengthy service life.

Several People Today are trying to produce roto-molded Products and working with renowned market frontrunners for such casting projects. However, with appointment, developing, then fabricating, an individual can get their products made by this procedure of molding very economically.